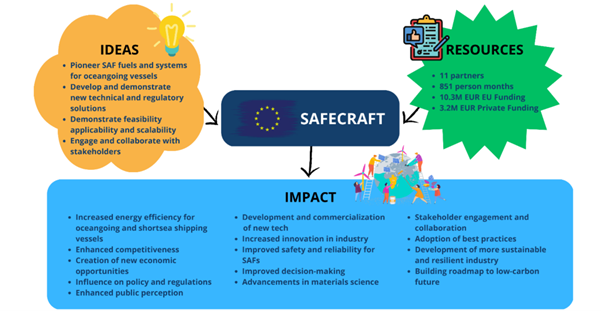

Approach/Methodology

SAFeCRAFT will showcase the entire A-Z approach required for the utilisation of SAFs, starting from the supply chain assessment, bunkering, storage, handling and finally, fuel consumption onboard, as well as the development of guidelines and best practices.

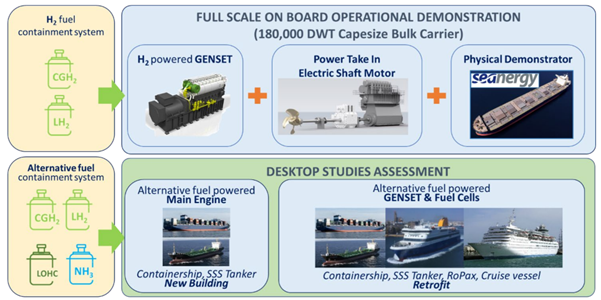

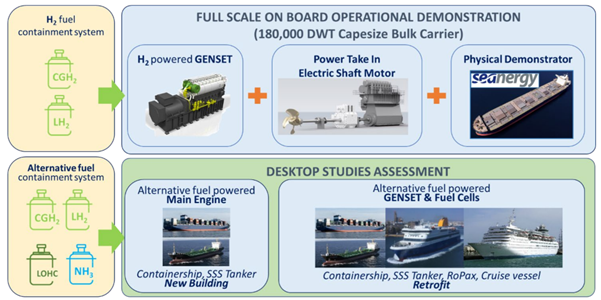

SAFs used will be demonstrated on a bulk carrier and assessed and validated through detailed desktop studies for four other types of vessels typical in EU ports. For the demo vessel, H2 will be used as the primary fuel source for a Generator Set providing power to a shaft motor (Power-Take-In) in parallel with the M/ E, thus covering part of ship’s propulsion needs. The desktop studies feature the previously mentioned SAFs that lead into three powertrain options for each vessel:

- fuel cell stacks & marine-type battery packs,

- internal combustion M/E (for new buildings),

- internal combustion PTI generator similar to the demo.

These SAF enabling power train systems will be analysed in-depth, using specific KPIs for safety, energy efficiency, environmental impact and techno-economic feasibility. SAFeCRAFT A-Z approach in utilising SAFs, including bunkering, storage, handling and fuel consumption onboard, and the issuance of Approval in Principle for the engineering and design processes, will accelerate their implementation.

To achieve the above, 8 development steps have been established and presented in Table 1. The proposed 8 development steps will be split in several work packages to be consistent and relevant to the call topics.

Table 1: SAFeCRAFT innovation development breakdown

|

No

|

Steps

|

Sub-steps

|

|

1

|

Development of a retrofit methodology for the 180,000 tons DWT Cape size Bulk Carrier

|

a) Design conditions and parameters

b) Implementation scenarios, feasibility assessments

c) Identification of challenges/solutions during retrofitting

|

|

2

|

Concept, basic and detailed engineering of the H2 GenSet power system with PTI/PTO

|

a) Determination of technical specifications of the power system

b) Selection of most promising type of PTI-PTO

c) Integration with detailed engineering studies

|

|

3

|

SAF systems analysis and comparison for different ship types and sizes - generalisation of method

|

a) Comparative study of alternative fuel systems for various types of oceangoing vessels

b) Evaluation of potential application of each technology to each vessel, including ICEs and FCs as final consumers c) Determination of technical and economic barriers of alternative fuel systems

d) Selection of the most promising type for alternative application scenarios

e) Evaluation of selected fuel systems regarding sustainability and circularity

f) Desktop studies of LH2, CGH2, LOHC and NH3 fuels systems on seagoing vessels

g) Retrofit and new building design studies

h) Modularity and scalability assessment

|

|

4

|

Full scale onboard operational Demonstration

|

a) Assembly and onboard Installation

b) Functionality testing of system

c) Physical demonstration

d) Performance monitoring and data collection

|

|

5

|

Smart digitalization of the engineering process

|

a) Digital Integration

b) Digital monitoring and operations tools

c) Virtual demonstration

d) Use of results for optimisation / predictive maintenance

|

|

6

|

Technical Guidelines for accelerated transition

|

a) Approval-in-Principle of vessel integration design

b) Development & dissemination of technical guidelines, best practices to industry stakeholders

|

|

7

|

Operational, risk and safety assessment of LH2, CGH2, LOHC and NH3 as a fuel

|

a) Safety and risk evaluation of the designed systems

b) Development of safety assessment guidelines and design recommendations

|

|

8

|

Techno-commercial evaluation of the proposed solutions

|

a) Life cycle assessment of alternative systems

b) Life cycle cost analysis of alternative systems

c) Techno-commercial assessment of demonstrator

d) KPI-based evaluation and technology

|